- Büyük Kayacık Mah. Org. San. Böl. 102. Cad. No:10 Selçuklu/Konya/TÜRKİYE

- +90 332 345 07 70

- +90 332 345 07 72

- bilgi@altundokum.com.tr

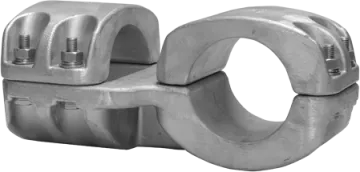

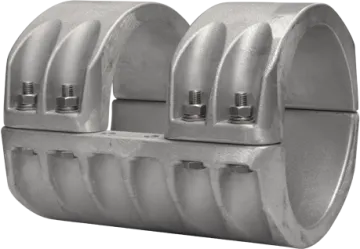

TUBE CONNECTORS

Tube Connectors

These are the terminal blocks that connect the pipes produced in pipe sizes suitable for the project to the pipes and the pipes to the devices. There are straight, lamella, footed, angled, parallel, special type Tube Connectors models.

Connectors Features and Usage Areas

In the terminal blocks made of materials that are magnetically dense in the production of high voltage lines, the change delay rate on the material caused by the current on it and the eddy current formed inside the terminal can cause too much heating in and around the terminal, a decrease in the strength of the connection points that already have a difficult mechanical task, and network drops. . Mains drops and overheating situations are less common in terminals made of aluminum alloy.

Jumps caused by direct weather opposition or deformed insulator chains under fog, the current from the cable to the pole, from the pole to the cable must be able to exceed the contact force between the cable and the terminal. If the contact between the conductive cables and the terminal is faulty, the wire may melt. In this case, aluminum alloy terminal blocks provide a high transition resistance due to their current-conducting feature.

Since the terminals are not very heavy, they reduce oscillations and losses. Since aluminum oxide has an insulating feature, the oxide layer in the sections where the conductor cables come into the terminal will make it difficult to pass the current, so maintenance should be done and those parts should be cleaned. Otherwise, these parts may overheat and the cables may melt.

!['.$Settings->MainMeta['title'].'](assets/site/images/logo.webp)